December 2025

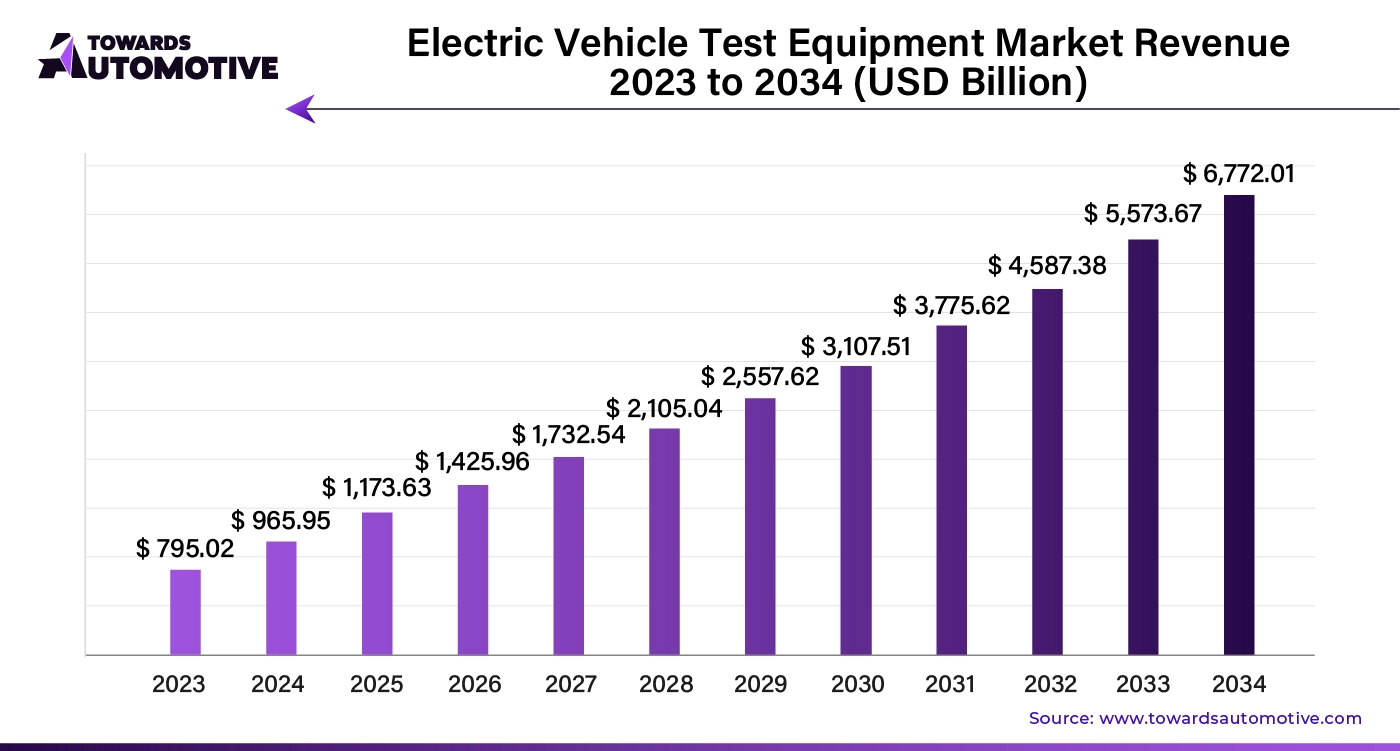

The electric vehicle test equipment market is forecasted to expand from USD 1,173.63 billion in 2025 to USD 6,772.01 billion by 2034, growing at a CAGR of 21.5% from 2025 to 2034.

The electric vehicle test equipment market is expanding rapidly, driven by the surge in EV adoption and the need for rigorous testing to ensure vehicle performance, safety, and compliance with evolving regulations. As automakers and suppliers ramp up production of electric vehicles, there is a growing demand for specialized testing equipment designed to evaluate various aspects of EVs, including battery performance, electric drivetrains, and charging systems. This includes advanced diagnostic tools, battery testers, and thermal management systems that assess battery efficiency and longevity, crucial for optimizing EV performance and reliability.

Additionally, the market is seeing innovations in simulation and testing equipment that support the development of autonomous and connected EV technologies. As the industry shifts towards higher standards for safety and environmental impact, testing equipment must adapt to address new challenges, such as evaluating the impact of extreme weather conditions on battery performance and ensuring the interoperability of different charging standards. Furthermore, advancements in testing technologies, including the integration of artificial intelligence and machine learning, are enhancing the accuracy and efficiency of EV testing processes.

These developments not only support the growth of the EV test equipment market but also drive the continuous improvement of electric vehicle technologies, aligning with global trends toward sustainable and smart transportation solutions.

Artificial intelligence (AI) plays a transformative role in the Electric Vehicle test equipment market by enhancing the accuracy, efficiency, and capabilities of testing processes. AI algorithms analyze data from EV test equipment to predict potential failures or maintenance needs before they occur. This predictive capability helps in minimizing downtime and extending the lifespan of testing equipment.

AI facilitates real-time analysis of complex test data, enabling quicker decision-making and more accurate assessments of EV performance. This is crucial for evaluating parameters such as battery health, charging efficiency, and overall vehicle dynamics. AI-driven automation streamlines testing procedures, reducing the need for manual intervention and increasing throughput. Automated systems can perform repetitive tests with high precision, ensuring consistency and reliability in test results.

AI enhances simulation models used in testing by providing more accurate predictions of how EVs will perform under various conditions. This includes simulations for battery behavior, thermal management, and driving scenarios, which are essential for optimizing EV design and performance.

AI systems can detect anomalies and deviations from expected performance metrics, allowing for early identification of potential issues. This helps in maintaining high standards of quality and safety in EVs. AI can analyze historical test data to optimize testing protocols and improve the efficiency of the testing process. This includes adjusting test parameters to better simulate real-world conditions and enhance the validity of test results.

The rising production of electric vehicles (EVs) is a significant driver of growth in the electric vehicle test equipment market. As the global automotive industry increasingly shifts towards electrification, the demand for sophisticated testing equipment has surged to ensure that EVs meet stringent performance, safety, and regulatory standards. With the production of EVs scaling up, manufacturers require advanced test equipment to assess various critical components, including batteries, electric drivetrains, and charging systems. This includes specialized tools for evaluating battery efficiency, thermal management, and charging protocols.

The expansion of EV production also necessitates rigorous testing to address challenges unique to electric vehicles, such as optimizing battery life and ensuring compatibility with diverse charging infrastructures. Furthermore, as new technologies and innovations emerge in the EV sector, such as autonomous driving and connected vehicle systems, the need for cutting-edge test equipment to validate these advancements grows.

The continuous development and integration of new testing technologies, including AI-driven diagnostics and real-time data analysis, further support the growth of the EV test equipment market. As automakers strive to enhance vehicle performance and meet evolving consumer expectations, the demand for reliable and accurate EV test equipment remains crucial, driving sustained growth and innovation in the market.

The Electric vehicle test equipment market faces several restraints that could impact its growth. High costs associated with advanced testing technologies and equipment pose a significant barrier, limiting accessibility for smaller manufacturers and startups. Additionally, the rapid pace of technological advancements necessitates frequent updates and recalibration of test equipment, increasing ongoing maintenance expenses. The complexity of integrating new testing protocols with existing systems also presents challenges. Furthermore, regulatory inconsistencies across regions can complicate compliance and standardization, creating hurdles for global market expansion and harmonization.

Wireless testing solutions are creating significant opportunities in the electric vehicle test equipment market by enhancing flexibility, efficiency, and ease of use. These solutions eliminate the need for physical cables and connectors, which streamlines the setup and execution of tests. Wireless technologies enable real-time data transmission from various EV components, such as batteries, drivetrains, and charging systems, allowing for more dynamic and responsive testing environments. This not only speeds up the testing process but also reduces the risk of interference and signal degradation associated with wired connections.

Furthermore, wireless testing solutions facilitate remote monitoring and control, enabling engineers to conduct tests from a distance and access real-time data without being physically present. This capability is particularly valuable for large-scale testing facilities and complex test setups. As EV technologies continue to advance, the need for adaptable and efficient testing methods grows, making wireless solutions increasingly important. By supporting greater mobility, reducing physical clutter, and enhancing data accessibility, wireless testing solutions are driving innovation and efficiency in the EV test equipment market, contributing to the rapid development and refinement of electric vehicle technologies.

The BEV segment held the largest share of the market. The Battery Electric Vehicle (BEV) segment is a major driver of growth in the electric vehicle test equipment market due to its unique testing requirements and the rapid expansion of BEV adoption. BEVs, which rely solely on electric power for propulsion, require extensive testing of their battery systems, electric drivetrains, and charging interfaces. This includes evaluating battery performance, efficiency, and safety under various conditions, as well as ensuring compatibility with different charging standards. The increasing production and sales of BEVs necessitate advanced test equipment capable of assessing these specific components accurately.

Additionally, the push towards higher energy densities and longer driving ranges for BEVs introduces new challenges in battery management and thermal control, further driving demand for sophisticated testing solutions. Innovations in battery testing, such as high-precision diagnostic tools and real-time performance monitoring, are essential to meet these evolving needs. As BEVs continue to dominate the electric vehicle market, the demand for specialized test equipment to ensure their reliability, efficiency, and safety will remain strong, fueling growth in the EV test equipment market and supporting the broader transition to electric mobility.

The passenger car segment led the market. The passenger car segment is a crucial driver of growth in the electric vehicle test equipment market, primarily due to its substantial share in the overall automotive market and the increasing focus on electric models. As passenger cars, especially electric ones, become more prevalent, there is a growing need for advanced test equipment to ensure their performance, safety, and compliance with industry standards. This includes rigorous testing of battery systems, electric drivetrains, and onboard electronics specific to passenger vehicles. The focus on optimizing range, efficiency, and driving dynamics for passenger EVs necessitates sophisticated diagnostic tools and testing solutions capable of handling the unique requirements of these vehicles.

Additionally, the shift towards smart and connected passenger cars, which incorporate features such as advanced driver assistance systems (ADAS) and infotainment technologies, further drives the demand for comprehensive testing equipment. The need to validate these systems' functionality and interoperability ensures that passenger EVs meet high standards of quality and performance. As the passenger car segment continues to evolve with technological advancements and increased consumer adoption of electric vehicles, the demand for specialized EV test equipment remains strong, propelling growth in the market and supporting the advancement of electric mobility.

The ev component & drivetrain segment dominated the industry. The EV component and drivetrain segment is a key driver of growth in the electric vehicle test equipment market, as it encompasses critical elements essential to electric vehicle performance and efficiency. Testing the myriad components that make up EV drivetrains—including electric motors, inverters, and power electronics—requires highly specialized equipment designed to ensure these systems operate reliably and meet stringent performance standards. The complexity and precision needed in testing these components drive demand for advanced diagnostic tools and test rigs capable of simulating real-world conditions and evaluating performance metrics accurately.

Additionally, as EV technology advances, new components and subsystems are continually introduced, necessitating the development of innovative test equipment to keep pace with these advancements. The focus on enhancing drivetrain efficiency, optimizing power delivery, and improving overall vehicle dynamics further fuels the need for sophisticated testing solutions. Furthermore, the growth of high-performance and specialty EVs, which often feature cutting-edge drivetrain technologies, increases the demand for precise and comprehensive testing. As the EV component and drivetrain segment continues to evolve, the requirement for advanced testing equipment becomes even more critical, driving market expansion and supporting the advancement of electric vehicle technologies.

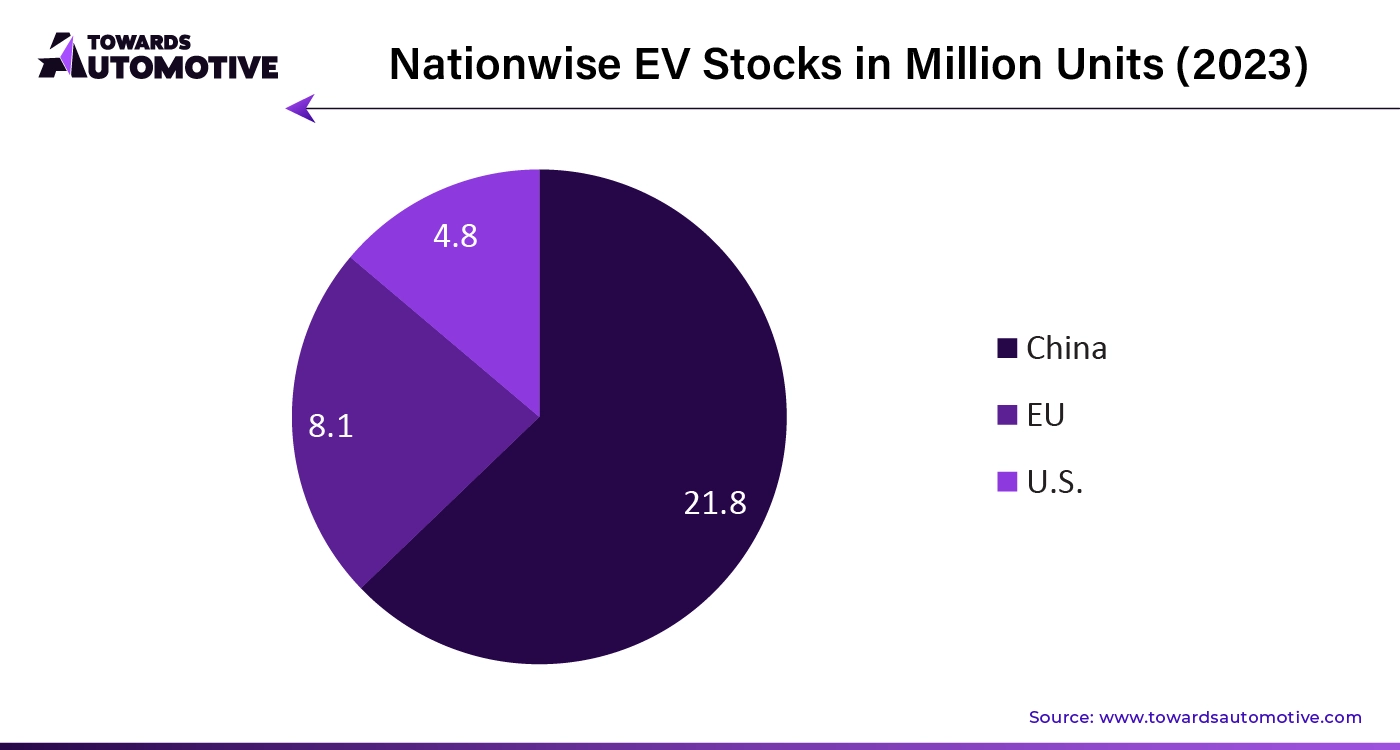

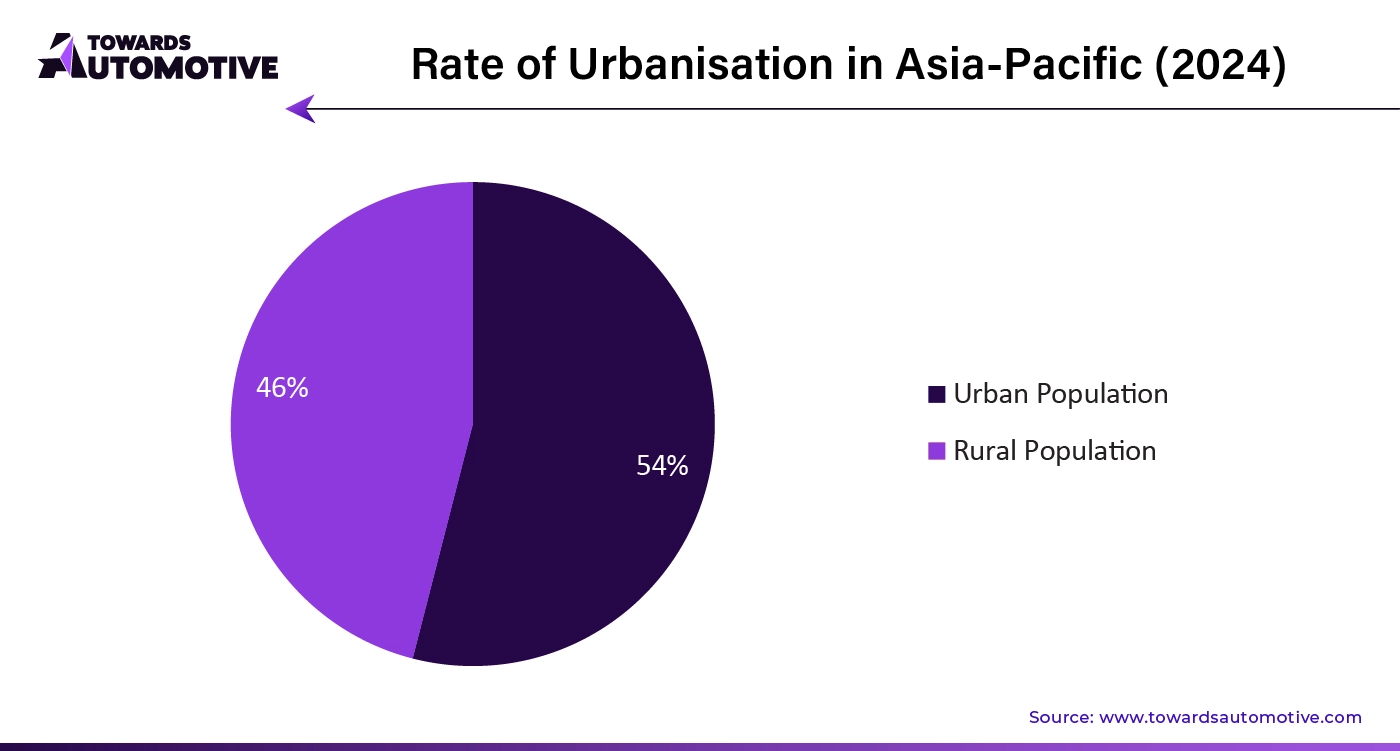

Asia Pacific dominated the electric vehicle test equipment market. The rapid growth in electric vehicle (EV) adoption, increasing focus on battery technology, and urbanization are pivotal drivers of the electric vehicle test equipment market in Asia Pacific. The region's surge in EV adoption, spurred by government incentives, environmental policies, and consumer demand, necessitates advanced testing equipment to ensure that the expanding fleet of EVs meets stringent performance and safety standards. Concurrently, the emphasis on battery technology—crucial for extending driving range and enhancing performance—drives demand for specialized battery testing equipment. Innovations in battery chemistry, such as solid-state batteries and high-capacity cells, require precise testing to validate their efficiency, safety, and longevity.

Urbanization, characterized by rapid city development and expanding infrastructure, further accelerates the deployment of EVs and the corresponding need for reliable testing solutions. As new charging infrastructure is integrated into growing urban areas, ensuring compatibility and safety becomes increasingly important. Together, these factors—rising EV adoption, advancements in battery technology, and urbanization—fuel the demand for sophisticated testing equipment in Asia Pacific, supporting the region's transition to a more sustainable and technologically advanced automotive landscape.

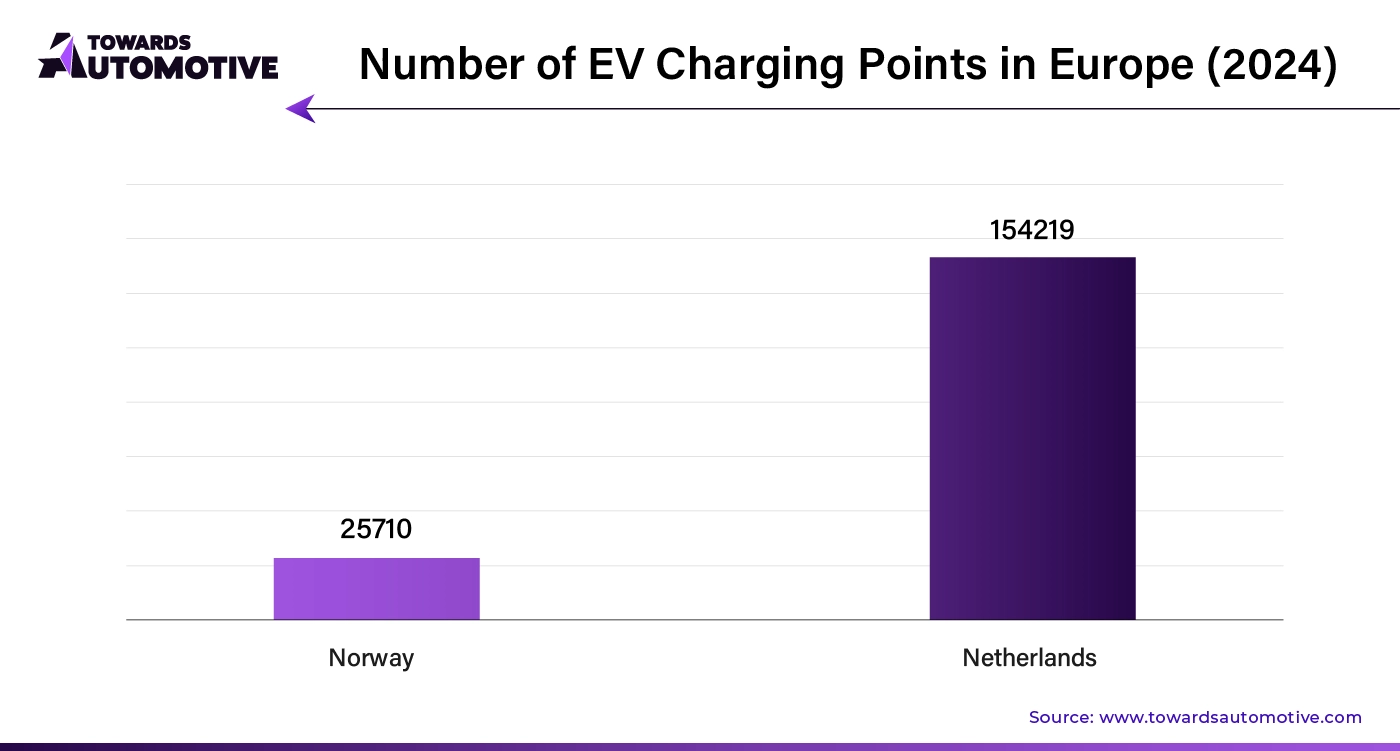

Europe is expected to grow with a significant CAGR during the forecast period. Technological innovations, expansion of charging infrastructure, and government incentives and support are key drivers of growth in the electric vehicle test equipment market in Europe. The region’s leadership in automotive technology fuels demand for advanced testing solutions to evaluate cutting-edge developments such as electric drivetrains, autonomous systems, and next-generation battery technologies. As these innovations continue to evolve, precise and sophisticated test equipment is essential to ensure performance, safety, and compliance with industry standards.

Concurrently, the rapid expansion of EV charging infrastructure across Europe necessitates rigorous testing of charging stations and related equipment to ensure compatibility, efficiency, and safety. This infrastructure growth supports widespread EV adoption and drives the need for reliable testing solutions. Government incentives and support further accelerate market growth by providing financial backing for EV adoption and R&D initiatives. These incentives encourage manufacturers to invest in new technologies and testing equipment to meet stringent regulatory requirements and market demands. Together, these factors—technological advancements, infrastructure development, and supportive policies—create a robust environment for the growth of the EV test equipment market in Europe, facilitating the region’s transition to a sustainable and technologically advanced automotive future.

By Propulsion

By Vehicle Type

By Application

By Region

December 2025

October 2025

October 2025

October 2025

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us