August 2025

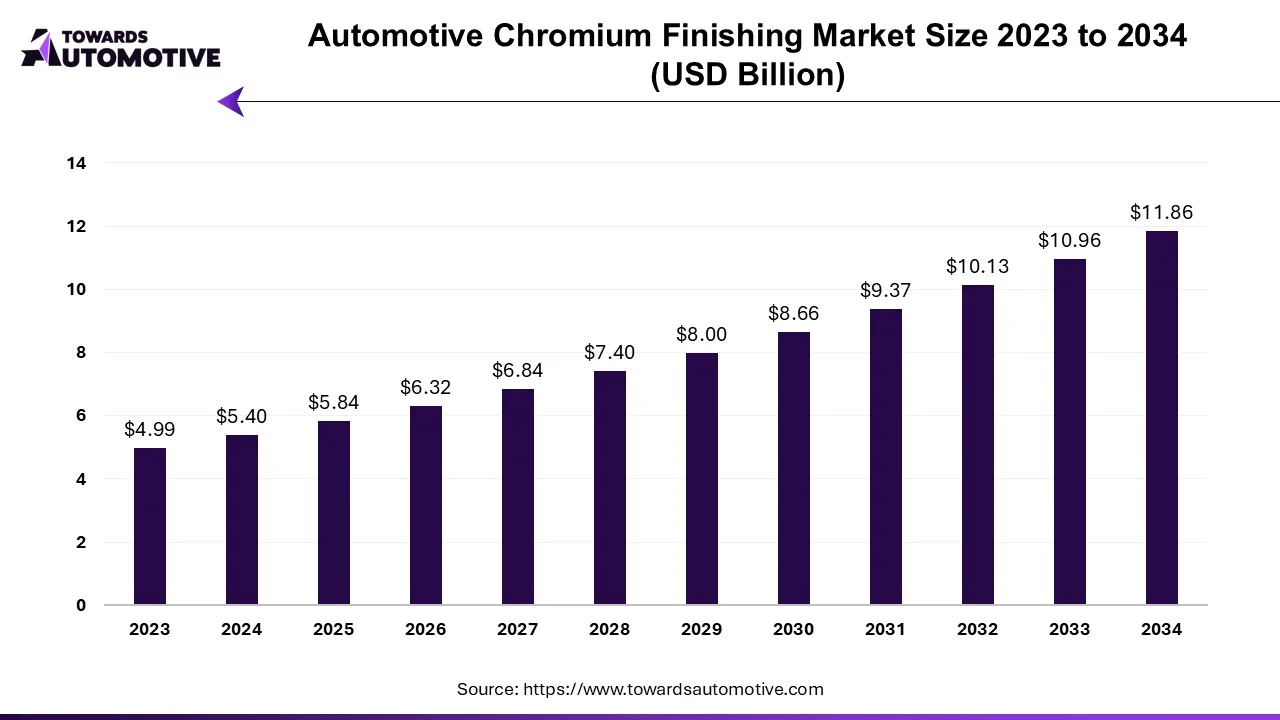

The automotive chromium finishing market is forecasted to expand from USD 5.84 billion in 2025 to USD 11.86 billion by 2034, growing at a CAGR of 8.19% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The automotive chromium finishing market plays a pivotal role in enhancing the aesthetic appeal, corrosion resistance, and durability of automotive components, contributing to the overall quality and performance of vehicles. As automotive manufacturers and consumers prioritize style, functionality, and longevity, the demand for high-quality chromium finishing solutions continues to rise. This blog explores the key components, market dynamics, trends, and outlook of the automotive chromium finishing market.

The automotive chromium finishing market comprises a diverse ecosystem of plating facilities, chemical suppliers, equipment manufacturers, and automotive OEMs involved in chromium plating and surface finishing solutions.

Some of the prominent players in the market include:

By Plating Type

By Application

By Vehicle Type

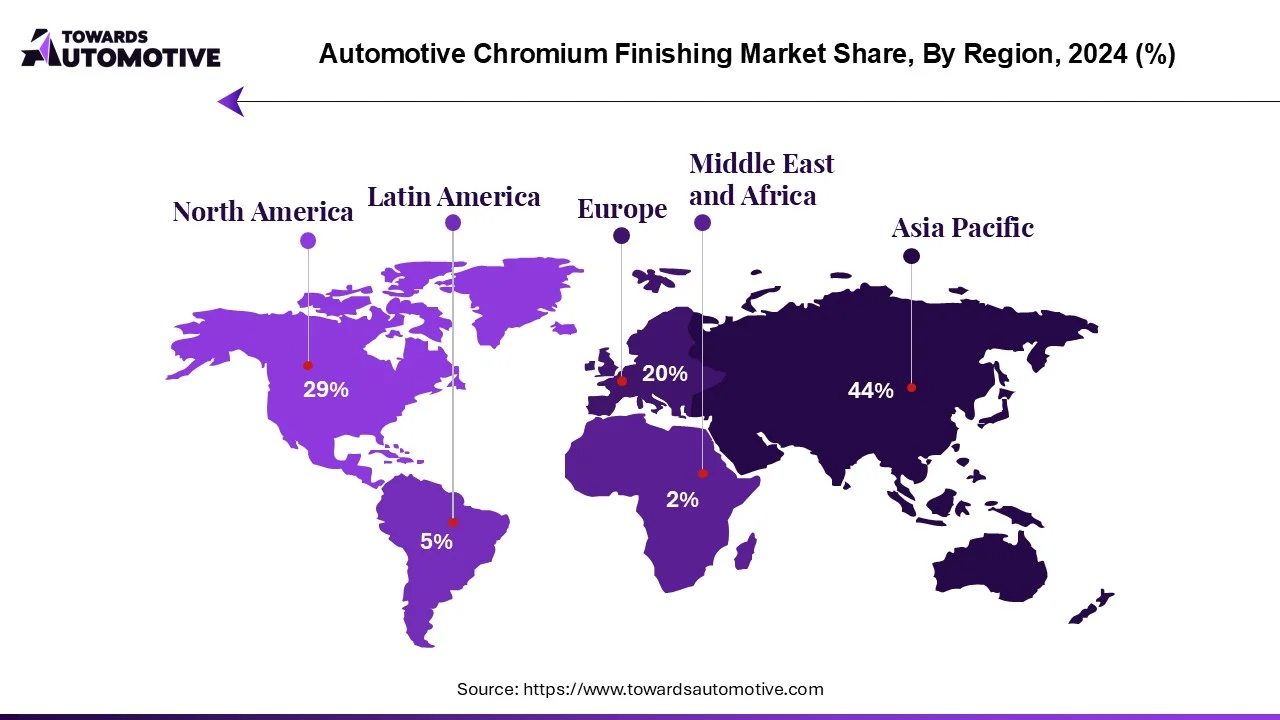

By Geography

§ North America

August 2025

August 2025

August 2025

July 2025

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us