October 2025

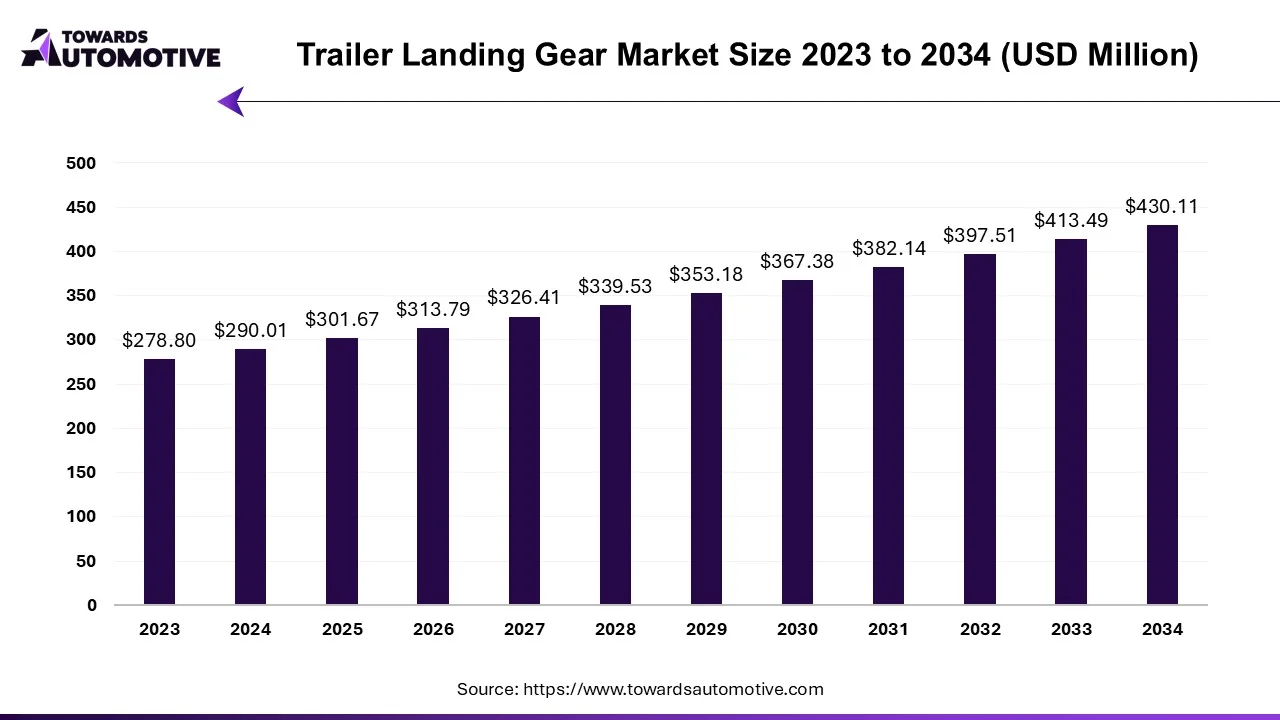

The trailer landing gear market is forecasted to expand from USD 301.57 million in 2025 to USD 430.11 million by 2034, growing at a CAGR of 4.02% from 2025 to 2034. The growing demand for heavy landing gears to provide additional stability to trailers when it is not connected to any source has boosted the market expansion.

Additionally, the rising demand for lightweight landing gears along with rapid deployment of heavy-duty trailers in the e-commerce sector has fostered the industry in a positive direction. The integration of advanced sensors in landing gears coupled with increased use of automated tools for controlling landing gears is expected to shape the industry in a positive direction.

The trailer landing gear market is a prominent branch of the commercial vehicle industry. This industry deals in manufacturing and distribution of trailer landing gears in different parts of the world. There are different types of landing gears including automatic gears and manual gears. These landing gears comes with various lifting capacity including less than 20000 lbs, 20000 lbs to 50000 lbs and above 50000 lbs. It is available in a well-organized sales channel comprising of OEM and aftermarket. The growing sales of heavy-duty trailers in different parts of the world has boosted the market expansion. This market is expected to rise significantly with the growth of the automotive sector around the globe.

| Metric | Details |

| Market Size in 2024 | USD 290.01 Million |

| Projected Market Size in 2034 | USD 430.11 Million |

| CAGR (2025 - 2034) | 4.02% |

| Leading Region | North America |

| Market Segmentation | By Type, By Sales Channel, By Lifting Capacity and By Region |

| Top Key Players | BPW Bergische Achsen KG, H.D. Trailers Pvt. Ltd., haacon, AXN Heavy Duty |

The major trends in this market consists of electric-powered landing gears, advancement in sensor technology, rise in number trailer rental companies.

The demand for electrically-powered landing gears has increased rapidly for extending and retracting wheels of trailers.

The technological advancements in sensors are crucial for handling the landing gears as sensors can optimize these gears according to the requirement.

There is a prominent rise in the number of trailer rental companies in different parts of the world, thereby increasing the demand for landing gears.

The manual segment dominated the market. The demand for manual handling gears has increased rapidly for stabilizing modern trailers, thereby driving the market expansion. Additionally, numerous benefits of manual trailer handling gears including cost savings, increased throughput, precise positioning and some others is expected to boost the growth of the trailer landing gear market.

The automatic segment is expected to grow with a considerable CAGR during the forecast period. The growing adoption of automated landing gears in developed nations has boosted the market growth. Also, various advantages of these landing gears including enhanced productivity, reducing injury risks, improved accuracy and some others is expected to propel the growth of the trailer landing gear market.

The above 50,000 lbs segment held the largest share of the industry. The growing demand for heavy-duty trailers in several industries such as coal, oil and gas, metals and some others has increased the application of above 50000 lbs landing gears, thereby driving the growth of the trailer landing gear market.

The 20,000 lbs to 50,000 lbs segment is expected to rise with a notable CAGR during the forecast period. The rising use of medium-duty landing gears for controlling light-duty trailers coupled with rapid investment by market players for developing landing gears of this range is expected to drive the growth of the trailer landing gear market.

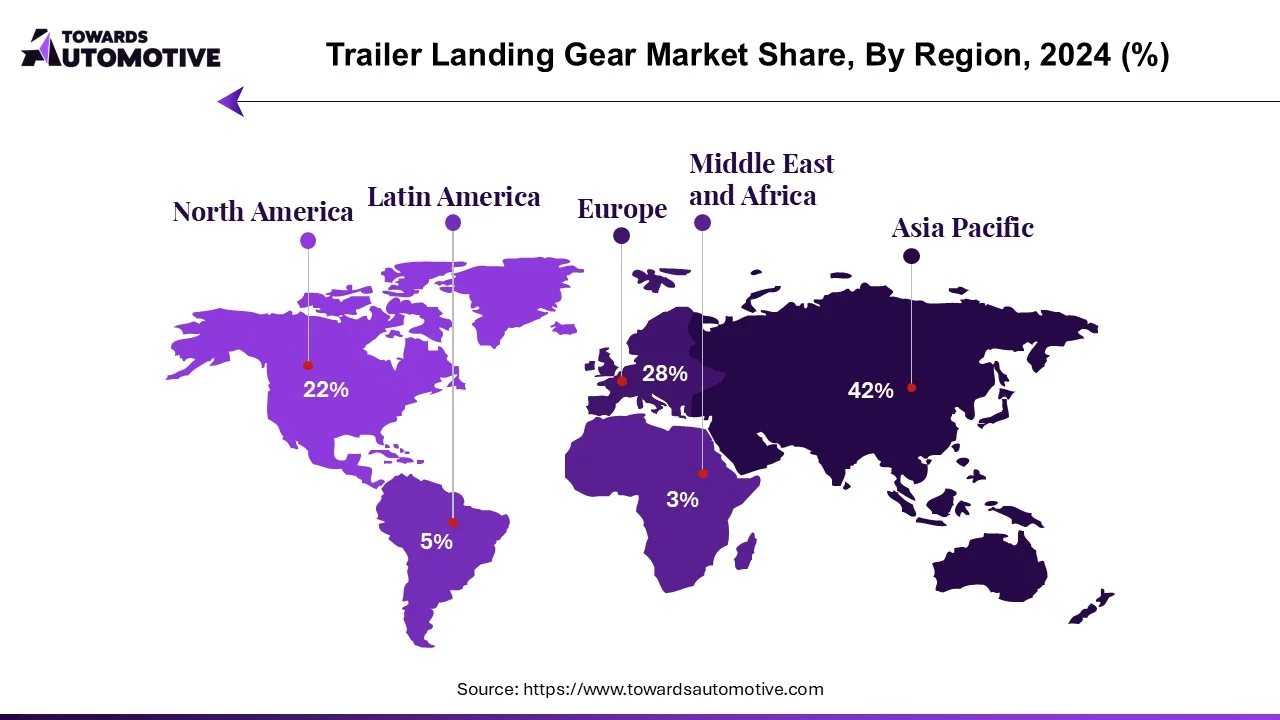

North America led the trailer landing gear market. The growing sales of semi-trailers in several countries such as the U.S. and Canada has boosted the market expansion. Additionally, the rise in number of residential constructions in Los Angeles and California as well as rapid investment by public companies for developing the trailer industry is playing a vital role in shaping the industrial landscape. Moreover, the presence of several market players such as AXN Heavy Duty, Hendrickson International, Holland LP and some others is expected to drive the growth of the trailer landing gear market in this region.

Asia Pacific is expected to grow with a significant CAGR during the forecast period. The rising adoption of automatic trailer landing gears among fleet operators has boosted the market expansion. Additionally, numerous government initiatives aimed at adopting electric trucks in several countries such as India, China, Japan and some others is contributing to the overall industrial expansion. Moreover, the presence of several landing gear companies such as Sinotruk Howo Sales Co., Ltd., Zhenjiang Baohua Semi-Trailer Parts Co., Ltd., H.D. Trailers Pvt. Ltd and some others is expected to propel the growth of the trailer landing gear market in this region.

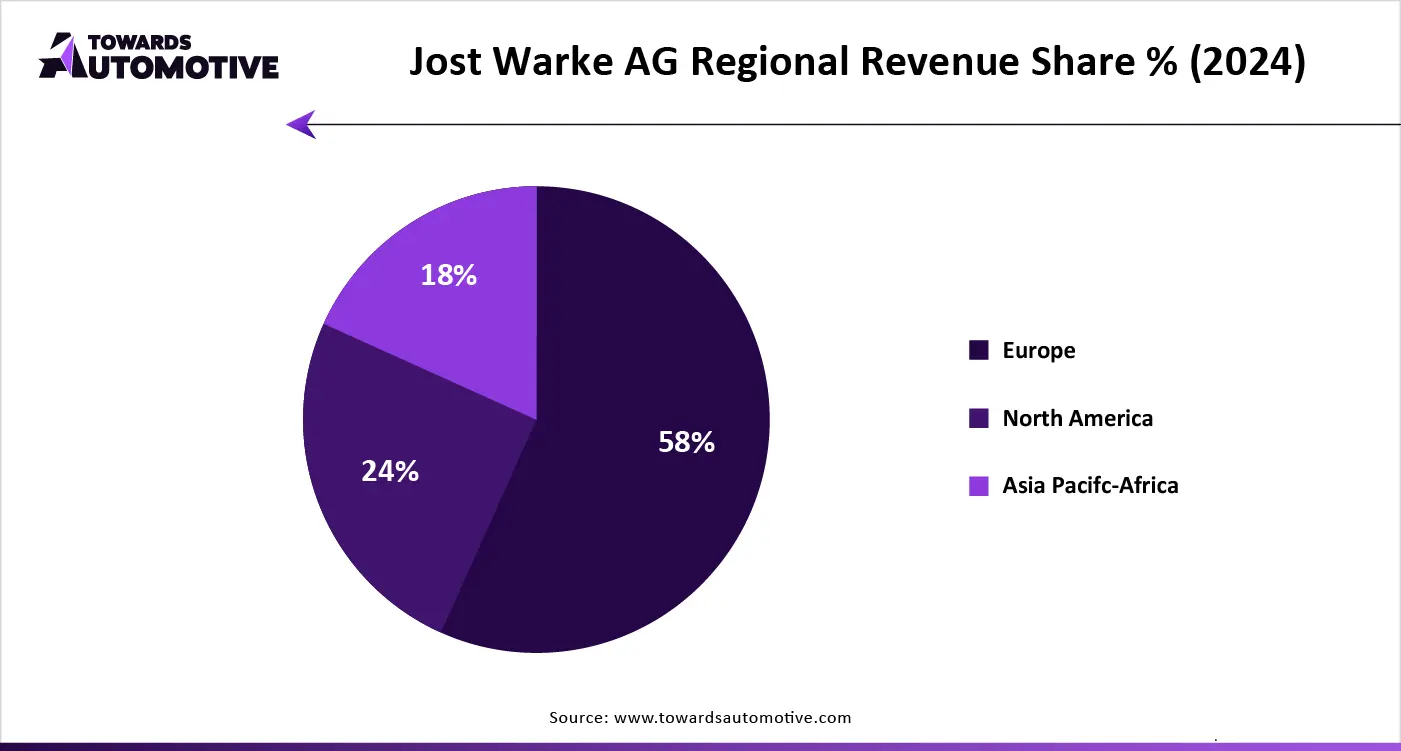

The trailer landing gear market is a highly fragmented industry with the presence of several dominating players. Some of the prominent companies in this industry consists of BPW Bergische Achsen KG, H.D. Trailers Pvt. Ltd., haacon, AXN Heavy Duty, Butler Products Corp., Fuwa Group, JOST Werke AG, SAF-HOLLAND, Sinotruck Howo Sales Co., Ltd., Yangzhou Tongyi Machinery Co., Ltd and some others. These companies are constantly engaged in developing coach buses and adopting numerous strategies such as acquisitions, joint ventures, collaborations, launches, partnerships, and some others to maintain their dominance in this industry.

By Type

By Sales Channel

By Lifting Capacity

By Region

October 2025

April 2025

April 2025

April 2025

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us